Smart Industry Open Innovation + Acceleration

Reach 70 Industry Leaders who act as Venture Clients by offering contracts to Startups for real Industry projects.

The BIND Open Innovation and Acceleration Program connects dynamic startup teams with well-established companies, to provide external solutions for their internal digital transformation challenges while promoting the development of commercial skills and encouraging the immersion of startups in the local ecosystem, catalyzing new business opportunities.

This zero-equity approach to investing and active acceleration allows startups to maintain ownership and get reference customers while earning paid contracts for implementing solutions in real environments.

Ready to work with paying clients on real use cases with the companies driving the Intelligent Industry, Clean Energy & Sustainability, Health and Food sectors?

What Startups Get

Seeking innovative technologies

The disruptive technologies of interest expand each year to meet the needs of the 70+ Corporate Clients from the sectors of Intelligent Industry, Clean Energy & Sustainability, Health Tech and Food Tech in the Basque region. If you have developed any related solutions, we encourage you to apply to put your innovation into action.

12 Business Use Cases for 2023 Open Call

In addition to the disruptive technologies in demand, the BIND Corporate Clients have prioritized 12 Use Cases that address current Industry Challenges. Apply today, if you have developed any technologies listed above, or solutions that address these Use Case challenges.

What To Expect…

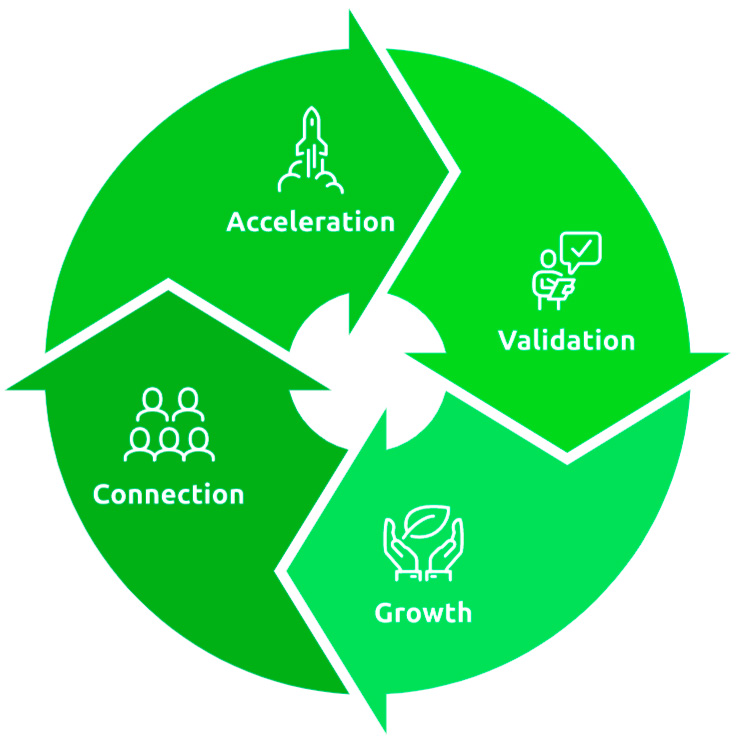

+ Connection

+ Acceleration

+ Validation

+ Growth

The BIND Open Innovation & Acceleration Program can be broken down into four interconnected phases.

JULY-SEPT

Call for Startups, Scouting Process and Pre-Selection of Desired Solutions.

SEPT-DEC

Pitching Sessions and Matchmaking with 70 Industry Leading Corporate Clients.

JAN-JUNE

High Impact Acceleration and Smart Industry Project Implementation.

YEAR ROUND

Innovation Showcase & Activities in Basque Industrial Ecosystem.

BIND Supports your Startup and puts your Innovation into Action

7 Editions Of Proven Success

With over 300 Smart Industry Projects realized since 2017, joining BIND means being part of an influential group of startups, corporates, investors and professionals forming a large business support network.

“BIND offers a unique opportunity to boost your project through a partnership with a leading company and accelerate your time to market”

“The combination of workshops, company visits and project collaboration is unique and useful for every startup.”

“The biggest advantage of taking part in BIND is the established community: BIND Team, world-leading corporates, mentors and startups altogether pursuing new challenges and solutions.”