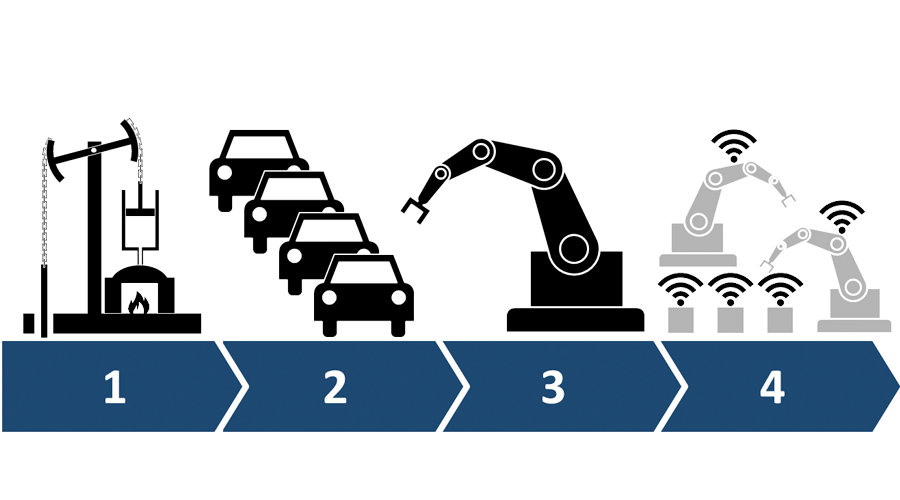

Industry 4.0 has matured in 2017 and interest in this term has doubled during the last 12 months. There are some clear trends in the technologies that surround this word, all of which merge software with hardware in companies that used to be focused on manufacturing physical objects.

These are some of those trends:

– More Industry 4.0 Startups. As the consumer Internet is not able to produce so many disruptive projects, investors are developing an interest towards B2B startups and specially Industry 4.0 ones. At the same time, big industrial corporations are increasingly looking at startups as an R&D engine.

– Digital transformation merging with Industry 4.0. As more companies want to transform their processes and products to become more digital, the opportunities of Industry 4.0 are becoming more attractive for those that manufacture objects.

– Industry 4.0 platforms becoming mainstream. As more software developers are glimpsing the opportunities of Industry 4.0, they are launching their own products in this field. For the big houses, this means platforms that are able to provide all sorts of services and integrate with different corporate programs.

– More hardware companies becoming software giant houses and the other way around. This affects industrial automation corporates as ABB or GE but also B2C ones as Amazon or Enterprise Software players as IBM or Salesforce, all of which are leading several Artificial Intelligence niches. Two other good examples are chip manufacturers Nvidia and Intel, which are becoming very powerful in AI and sensor technology, and Autodesk in Additive Manufacturing.

– Machinery becoming smarter with AI. As hardware and software merge, new robots are coming to the market which are able to self-detect problems (“predictive maintenance”) and dramatically improve their performance. As additive manufacturing, big data and IoT are added to machines, more complex products are being developed.

– New forms of human-machine interaction. As new touch interfaces and augmented reality systems are being applied to the industrial world, a revolution is developing in so called smart factories. Increases in productivity and new offers of service are the engines that drive it.

– New sales options based on the performance of machines. As predictive maintenance and performance are being introduced into robots, manufacturers can guarantee a certain performance and price its usage on indicators that can be measured continuously.

– Cybersecurity is becoming a need. All companies entering the Industry 4.0 field are realizing that the new opportunities come together with high risks that need to be assessed. This means a big business for security houses that are able to merge hardware and software.

– Metal Additive Manufacturing becoming a reality. While investments in 3D Printing slowed down in 2016 because of lower B2C expectations, industry applied technologies have improved a lot in the last months. American venture capital funds True Ventures, Lux, Khosla, Asimov, and SOSV have been very active in this field.

Image: Christoph Roser